SiSAl project details

Proposal Number

20255

Lead Partner

Norwegian University of Science and Technology (NTNU)

Area

D2 Acceleration

Segment

D2.2 Upscaling

Duration

2021-01-03 - 2023-12-31

Welcome to

our project!

our project!

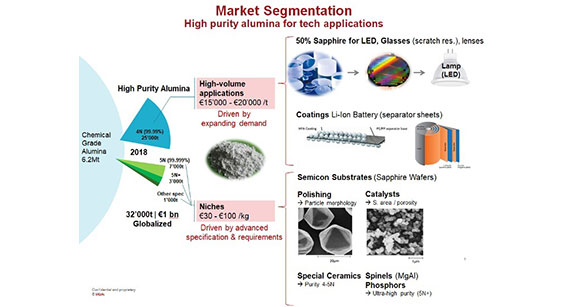

Today Silicon (Si) and High Purity Alumina (HPA) are made non-sustainably; for each tonne of Si you produce a lot more CO², plus harmful pollutants.

This problem is resolved by SisAl, by replacing carbon with secondary Al for Si production, and in parallel making a slag being a perfect precursor for HPA. If successful in upscaling, NTNU through a spin-off (licences), SiQAl & Mytilineos (HPA) and CALEF (CO² looping) will commercialise the sustainable technologies and products.

The Sisal concept comprises 3 main technologies:

- Silicon metal and SisAl slag production using the SisAl process

- HPA production from SisAl slag by the SiQAl process

- Mobile CO² looping unit that can be integrated in the processing of SisAl slag for HPA production and 2 main products

And 2 main products:

- Silicon metal (Si)

- High purity alumina (HPA)

Theoretical

Background

Background

A new, CO² free process for production of the critical raw material silicon (“SisAl”, see figure 1a and b), using secondary materials, has been developed to large laboratory/small pilot scale and patented by NTNU under the umbrella of the Norwegian centre “CRI Metal Production”.